Showing posts with label control. Show all posts

Showing posts with label control. Show all posts

4/09/2013

Wideband Sense & Heater Control ADC muxing 74HC4052

The dual 4 to 1 line mux U4 (74HC4052) allows two groups of four signals to be sensed by the microcontroller's two ADC input lines ADC0 and ADC1.

Wideband signals Vsx5, Ih, Vsx1, IpSense, DACV & Cal (VGND) voltages are sensed as well as H- via filtering provided by R112 and C103. also shown here is the H+ sense signal but it is not selected by the mux, but rather passed directly to the microcontroller via filter components R111 and C102.

Analogue user channel 1 USR1 (see Y5 connector input below) is also sensed by this mux.

4/02/2013

3/20/2013

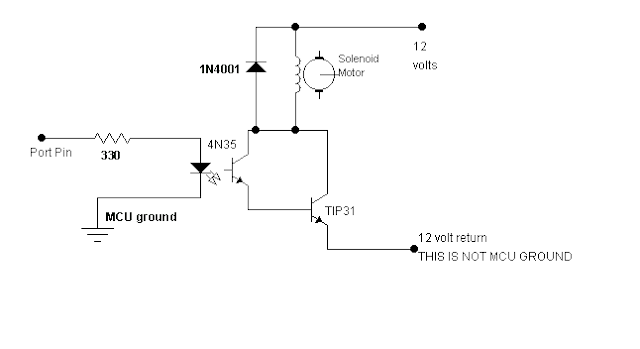

Solenoid and Sensor Control 4N35

To control the solenoid motors, we elected to use optoisolators. The control pins of the MCU were attached to the optoisolators which turns on and off the solenoid by controlling a TIP31 transistor. The TIP31 serves as an on/off switch for the solenoid. The optoisolators (4N35) were needed so that the MCU was completely isolated from the circuit. This protected the MCU because there were no physical connection between the MCU and the power supply. The 4N35 works by using a phototransistor that senses LEDS when the device is turned on.

The sensors were measured by a voltage division circuit coupled with an operational amplifier to achieve the desired results. The voltage outputted from the sensors was sent to the ADC of the MCU. The reference voltage of the MCU ADC was set to 5.0 volts which would correspond to the digital value 255 since only the top 8 bits of the ADC were used. We simply used this digital value to determine exactly how much juice we have dispensed.

2/28/2013

The inverter failure-tolerant control of single-phase sine wave is studied BTA16-600B

The failure-tolerant control purpose lies in directing against different trouble sources and symptoms, take the corresponding fault-tolerant processing measure, compensate for trouble, dispel or repair automatically, in order to guarantee the apparatus continues safe reliability service, or regard sacrificing characteristic losses as the cost, guarantee the apparatus finishes its basic function within stipulated time. If you want to adopt failure-tolerant control, have structure or redundancy functionally in the real-time analysis system at first. Find through analyzing, as to the inverter circuit of single-phase full-bridge, in fact the structural redundancy exists. Can regard the whole-bridge circuit as the superposing of two pieces of half bridge converter, if can be after the gas switching tube trouble of the power of a bridge arm of the inverter of the full-bridge, blockade this bridge arm, reconstruct the characteristic of certain holding circuit as the half bridge converter of the whole-bridge circuit, realize failure-tolerant control. Fig. 1 is the equivalent electrical circuit that the circuit reconstructs after full-bridge circuit topology with fault-tolerant capability and first, two bridge arm switch troubles.

In Fig. 1a, divides into two the electric capacity C1 as half bridge converter of the direct-flow Filtering capacitance in the whole-bridge circuit, C2, links the first bridge arm middle point A with two electric capacity middle points o with the bidirectional thyristor VTr1, the bidirectional thyristor VTr2 links the second bridge arm middle point B with point o, forms full-bridge circuit topology with fault-tolerant capability in this way.

Normal working hour, VTr1, VTr2 is the off state, the circuit equivalent is the normal full-bridge inverter circuit. After the trigger impulse takes place and lose the trouble in the power tube VM1, adopt the fault-tolerant control strategy to close the power tube VM3 of the same bridge arm, touch off VTr2 to turn on at the same time, VTr1 keeps off, the whole-bridge circuit is reconstructed as the half bridge converter, the circuit equivalent, in order to pursue 1b at this moment. After the trigger impulse takes place and lose the trouble in the power tube VM2, adopt the fault-tolerant control strategy to close the power tube VM4 of the same bridge arm, touch off VTr1 to turn on at the same time, VTr2 keeps off, the whole-bridge circuit is reconstructed as the half bridge converter, the circuit equivalent, in order to pursue 1c at this moment. The original control device should carry on corresponding adjustment according to the change of the control objective after the circuit is reconstructed, in order to guarantee the characteristic maintains at the acceptable range.

Sum up the fault-tolerant control strategy as follows, suppose VMi i =1,2,3,4The trigger impulse is lost. The whole fault-tolerant control process can be divided into the following several step: Judge the switch position of the trouble in fault detection and diagnostic circuitry; Blockade the trigger impulse of power switch on VMi and the same bridge arm in control unit, touch off the bidirectional thyristor which connects this bridge arm; The control unit changes the controller parameter, it is topological after make it adapt to reconstructing.

On the foundation of analyzing in the principle and artificial experiment, have designed and made a low-powered experimental provision. The experimental parameter is: Switching frequency fs =10 kHz; Export the filtering inductance L =1 mH; Filtering capacitance C of the output =20 F; Input the Filtering capacitance C1 =C2 =1 000 F; Direct-flow input voltage Uin =48 V. All power switches adopt the power MOSFET of the Model IRF650A, the output voltage adopts the voltage to isolate the man of great talent AD202 to measure after partial pressure. The output current measures and adopts the electric current transducer of Hall of Model CSB6-50A. The sense resistor of electric current of elementary straight flow side adopts 4 times 0. The resistance of 3 / 2 W is connected in parallel. Input the filtering resistance and is formed by two pieces of 1 000 F electric capacity, o some connect A, B bipunctate with VTr2 by VTr1. The bidirectional thyristor chooses BTA16-600B, drive and choose the bidirectional thyristor to drive special purpose chip MOC3 021. The main control chip of the circuit adopts the Model TMS302LF2407A DSP, is finished implementation of failure diagnosis and fault-tolerant tactics by it.

Experimental analogy VM1 is on the appointed phase place 90 degrees, 170 degrees, 270 degrees The trigger impulse takes place to lose the trouble, after the testing signal is judged by DSP trouble diagnostic element, carry out the fault-tolerant control procedure, blockades VM2 trigger impulse, touches off VTr1, it is 2 fold to change the given sine wave uref.

1/21/2013

TIP122 Connection Diagram

TIP122

Speed control of permanent-magnet (PM) dc motors with the aid of optical or dc tachometers is generally inconvenient and difficult, particularly on motors with integral gearboxes. The high-speed shaft of the motor that drives the gearbox isn't always accessible and the speed of the geared-down shaft often is too low for tachometers. Described here is a single-supply regulating speed-control circuit that doesn't require a tachometer. It keeps the motor torque high under load by using positive feedback to compensate for the drop caused by armature resistance. In unregulated variable-speed PM dc motor systems, the drop in speed under load is particularly pronounced at low motor-supply voltages. The positive feedback generates a negative resistance that compensates for the nonlinear effects caused by armature resistance. It thereby ensures that the speed-control input voltage (Vi) linearly controls the speed of the motor. Armature resistance compensation is achieved if:

RS= RA/[gain(R3) / (R3 + R4)] - 1

The divider action of R3 and R4 together with the gain reduces the value required for Rs to minimize the power dissipation. C1 and R4 dampen the positive-feedback signal's response time, but they also form a low-pass filter and attenuate the motor current noise fed to the A2 input. The maximum output voltage swing from A2 is approximately VCC-2 V, and there is a 1.2-V Vbe loss by T1. This implies that the supply voltage (Vcc) should be about 5 V above the maximum desired motor voltage in order to allow for extra output drive to the motor under heavy load conditions. A reason-able choice for Rs is approximately RA/10, and the gain of A2 should be trimmed with RV2 to ensure that the motor's speed does not drop when loaded.

11/26/2012

LM386 based stereo audio amplifier with digital volume control

Due to its simplicity (requires minimum external components) and high availability, LM386 is very popular among hobbyists for use in low-voltage audio amplification applications. Most of the time a potentiometer is used at the input side of LM386 to provide a volume control in the output speaker. The potentiometer does not control the gain of the amplifier itself, but it creates a voltage divider network at the input, which in fact controls the fraction of the audio signal that is fed to the amplifier. This project is about a stereo audio amplifier using two LM386 ICs with digital volume control for both left and right speakers. So, how would you control the volume digitally?

You are right, by replacing the traditional electro-mechanical form of potentiometers with digital potentiometer chips. This project uses MAXIM’s DS1868 dual digital potentiometer chip and a PIC microcontroller to control the volume of a stereo output from two LM386 ICs.

Subscribe to:

Posts (Atom)